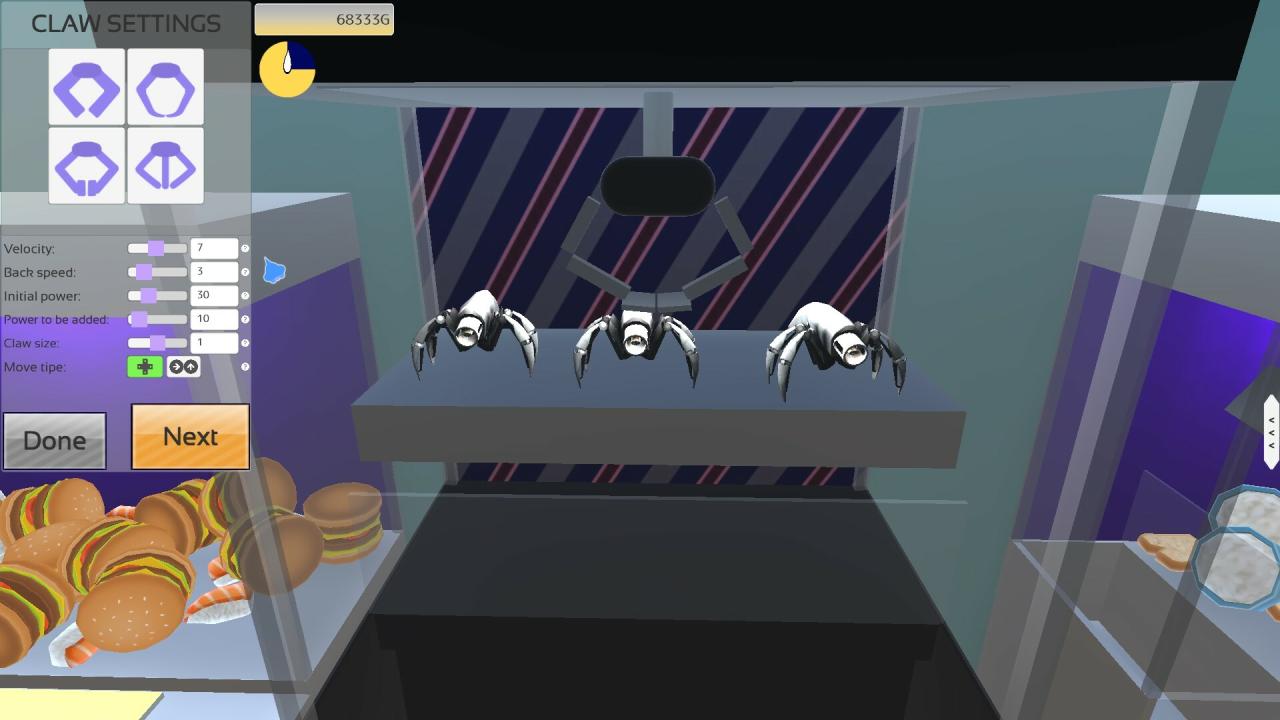

Claw Crane Mechanics

Claw cranes, also known as crane games or grabber machines, are a popular form of amusement found in arcades, carnivals, and even grocery stores. These machines operate based on simple yet effective mechanical principles that allow players to try their luck at grabbing prizes.

Components of a Claw Crane Control System

The control system of a claw crane is responsible for translating player input into precise movements of the claw. It consists of several key components, including:

- Motors: These are the driving force behind the claw’s movement. They can be electric motors, typically DC motors, responsible for rotating the claw, moving it up and down, and controlling its lateral movement. The type and size of motors determine the claw’s speed, power, and lifting capacity.

- Sensors: Sensors play a crucial role in providing feedback to the control system. Position sensors, such as potentiometers or encoders, track the claw’s position in space, allowing for accurate control. Other sensors, such as limit switches, ensure the claw doesn’t move beyond its designated boundaries.

- Actuators: Actuators are responsible for converting electrical signals from the control system into mechanical movement. They can be solenoids, hydraulic cylinders, or pneumatic actuators, depending on the specific design of the claw crane. These actuators control the opening and closing of the claw, as well as its gripping force.

- Control System: The control system is the brain of the claw crane. It receives input from the player, processes it, and sends signals to the motors and actuators to execute the desired movement. The control system can be a simple microcontroller or a more sophisticated PLC (Programmable Logic Controller) depending on the complexity of the claw crane.

Types of Claw Crane Mechanisms, Claw crane control system stellar blade

Claw cranes can be categorized into two main types, based on the mechanism used to grab prizes:

- Electromagnet-Based Systems: In this type of claw crane, an electromagnet is used to pick up prizes. When the electromagnet is energized, it creates a magnetic field that attracts ferromagnetic objects. When the current is switched off, the magnetic field collapses, releasing the prize. These systems are often used for grabbing metal prizes, such as toys or small metal objects.

- Gripper-Based Systems: These systems utilize a mechanical gripper to grab prizes. The gripper typically consists of two or more jaws that are controlled by actuators. When the jaws close, they grasp the prize. Gripper-based systems are more versatile and can be used to grab a wider range of prizes, including plush toys, plastic objects, and even small electronic devices.

Stellar Blade Technology: Claw Crane Control System Stellar Blade

The “Stellar Blade” technology represents a significant leap forward in claw crane control systems. It utilizes advanced algorithms and sophisticated hardware to deliver unparalleled precision, control, and efficiency, surpassing the limitations of traditional systems.

Enhanced Precision and Control

The Stellar Blade technology employs a multi-layered approach to achieve exceptional precision and control. It integrates a range of components and functionalities that work in synergy to optimize claw movement and target acquisition.

- High-Resolution Sensors: Stellar Blade systems are equipped with high-resolution sensors that provide real-time data on the claw’s position, orientation, and movement. These sensors, often employing advanced technologies like laser-based distance measurement or high-definition cameras, enable the system to track the claw’s trajectory with remarkable accuracy.

- Advanced Control Algorithms: Stellar Blade technology incorporates sophisticated control algorithms that analyze the sensor data and translate it into precise claw movements. These algorithms account for factors like gravity, wind resistance, and the weight of the target, ensuring smooth and controlled operation.

- Real-Time Feedback Loop: The Stellar Blade system operates on a real-time feedback loop, continuously adjusting the claw’s movement based on the sensor data. This dynamic feedback mechanism ensures that the claw stays on course and compensates for any deviations or external influences.

Control System Architecture

The Stellar Blade claw crane control system is designed to be a robust and reliable system capable of managing the complex movements and operations of the crane. This section delves into the architectural framework of the control system, outlining its communication protocols, data flow, and software and hardware components.

Communication Protocols and Data Flow

The control system utilizes a combination of communication protocols to ensure seamless data exchange between its various components. The primary protocol is a high-speed serial communication protocol like CAN bus (Controller Area Network), which is known for its reliability and efficiency in real-time applications.

The data flow within the control system follows a hierarchical structure, with the central control unit acting as the main hub. The central control unit receives input data from various sensors, such as position sensors, load sensors, and limit switches. It processes this data and generates control signals for the actuators, including the claw motor, arm motor, and base rotation motor.

Software and Hardware Components

The Stellar Blade claw crane control system comprises a comprehensive set of software and hardware components, each playing a crucial role in the system’s operation.

Hardware Components

- Central Control Unit (CCU): The CCU is the brain of the control system. It is typically a microcontroller or a dedicated control board with embedded software that manages the entire operation of the crane. It receives input data from sensors, processes it, and generates control signals for actuators.

- Sensors: Various sensors are integrated into the claw crane to provide feedback on its position, load, and other critical parameters. These include:

- Position Sensors: These sensors, such as encoders or potentiometers, track the position of the claw, arm, and base. They provide real-time feedback to the CCU, enabling precise control of the crane’s movements.

- Load Sensors: Load sensors, such as strain gauges, measure the weight of the object being grasped by the claw. This information helps the CCU adjust the claw’s gripping force and prevent overloading.

- Limit Switches: Limit switches are safety devices that prevent the crane from exceeding its operational boundaries. They are typically installed at the end of each axis’s travel range to prevent damage or accidents.

- Actuators: Actuators are the motors and other mechanical components that translate the control signals from the CCU into physical movements of the crane. They include:

- Claw Motor: The claw motor controls the opening and closing of the claw, allowing it to grasp and release objects.

- Arm Motor: The arm motor controls the vertical movement of the arm, allowing the claw to reach different heights.

- Base Rotation Motor: The base rotation motor allows the entire crane to rotate horizontally, enabling the claw to reach different locations within its operating range.

- Human-Machine Interface (HMI): The HMI is the user interface for the control system. It can be a touchscreen display, a set of buttons, or a combination of both. The HMI allows the operator to control the crane, monitor its status, and access various settings.

Software Components

- Control Software: The control software is the core of the control system. It runs on the CCU and is responsible for managing the entire operation of the crane. It includes:

- Sensor Data Acquisition: The software collects data from various sensors and processes it to provide accurate feedback on the crane’s state.

- Control Algorithm: The control algorithm uses the processed sensor data to generate control signals for the actuators, ensuring smooth and precise movements of the crane.

- Motion Planning: The software plans the optimal path for the claw to move from its current position to the desired target location, taking into account constraints such as obstacles and payload weight.

- Safety Mechanisms: The software incorporates safety mechanisms to prevent accidents and ensure the safe operation of the crane. These include limit switches, overload protection, and emergency stop functionalities.

- HMI Software: The HMI software provides the user interface for the control system. It allows the operator to interact with the crane, configure settings, and monitor its status. The HMI software is typically designed to be user-friendly and intuitive, making it easy for operators to control the crane effectively.

Programming and Calibration

Programming and calibrating the Stellar Blade-equipped claw crane control system is crucial for achieving optimal performance and ensuring safety. This process involves configuring various parameters and setting up the system to respond accurately to user inputs and environmental conditions.

Configuring Parameters

Configuring parameters allows for fine-tuning the claw crane’s behavior, ensuring it operates efficiently and safely. These parameters include:

- Claw Speed: This determines how quickly the claw moves. A higher speed is beneficial for fast retrieval, while a slower speed provides more control for delicate items.

- Grip Force: This parameter controls the strength of the claw’s grip. A strong grip is necessary for securely holding heavy objects, while a lighter grip is suitable for fragile items.

- Movement Trajectories: This allows defining the path the claw takes to reach a specific target. Sophisticated trajectories can be programmed to avoid obstacles and optimize movement efficiency.

Calibration

Calibration is a vital step in ensuring the claw crane operates accurately and safely. It involves aligning the claw’s movement with the actual physical system, guaranteeing precise control and avoiding potential collisions. Here’s a typical calibration procedure:

- Establish Reference Points: Define specific points on the claw crane’s structure as reference points. These points are used to establish a coordinate system for calibration.

- Move the Claw: Command the claw to move to each reference point, noting the actual position of the claw.

- Compare and Adjust: Compare the commanded position with the actual position of the claw. If there are discrepancies, adjust the control system’s parameters to minimize these differences.

- Repeat and Fine-Tune: Repeat steps 2 and 3 for all reference points, iteratively adjusting the parameters until the desired accuracy is achieved.

Calibration ensures that the claw crane’s movement is precisely aligned with the programmed commands, minimizing errors and ensuring safe operation.

Advanced Features and Applications

The Stellar Blade control system, with its precision and adaptability, lays the foundation for a range of advanced features and applications. By integrating cutting-edge technologies like object recognition and AI-powered decision-making, the system can be enhanced to offer greater functionality and versatility, extending its reach beyond traditional claw crane games.

Object Recognition and AI-Powered Decision-Making

The Stellar Blade control system can be further enhanced with the integration of object recognition and AI-powered decision-making capabilities. This integration would allow the system to identify specific objects within the claw crane’s grasp, enabling it to make more informed decisions about how to pick up and manipulate objects.

For instance, the system could be trained to recognize different types of plush toys, allowing it to adjust its grip strength and movement patterns based on the object’s size, shape, and texture. This would lead to a more successful and efficient retrieval process, minimizing the chances of dropping or damaging prizes.

Additionally, the system could be programmed to learn from its experiences, analyzing past attempts and successes to improve its decision-making in real-time. This AI-driven approach would allow the system to adapt to new objects and scenarios, continuously refining its performance and maximizing its success rate.

Applications Beyond Traditional Claw Crane Games

The Stellar Blade technology, with its precise control and adaptability, holds potential for applications beyond traditional claw crane games. This technology can be adapted for use in various fields, including industrial automation, robotics, and even healthcare.

- Industrial Automation: Stellar Blade technology can be implemented in industrial settings for tasks requiring precise manipulation of objects. For example, it could be used to assemble intricate components in manufacturing lines, handling delicate items with care and accuracy.

- Robotics: The system’s advanced control capabilities can be integrated into robotic systems, enabling them to perform tasks requiring dexterity and precision. This could include tasks like surgery, where the system could assist surgeons with delicate procedures, or in disaster relief, where robots equipped with Stellar Blade technology could navigate hazardous environments and assist in rescue operations.

- Healthcare: The Stellar Blade technology can be utilized in healthcare settings for tasks requiring delicate handling of objects. For example, it could be used in medical laboratories to manipulate samples, or in rehabilitation centers to assist patients with physical therapy exercises.

Enhancement of User Experience and Efficiency

The Stellar Blade technology can be used to enhance the user experience and improve the efficiency of claw crane operations.

- Enhanced User Experience: By incorporating features like object recognition and AI-powered decision-making, the Stellar Blade control system can provide players with a more engaging and rewarding experience. The system can analyze the player’s preferences and adjust its strategies accordingly, increasing the chances of success and providing a more personalized gaming experience.

- Improved Efficiency: The Stellar Blade technology can also be used to improve the efficiency of claw crane operations. By minimizing the number of unsuccessful attempts and optimizing the retrieval process, the system can reduce downtime and increase the number of prizes dispensed per hour. This can lead to increased revenue and improved customer satisfaction.

Claw crane control system stellar blade – The Stellar Blade control system represents a significant leap forward in claw crane technology, ushering in an era of precision, control, and enhanced user experience. From its advanced mechanics to its potential applications beyond traditional games, the Stellar Blade technology promises to revolutionize the way we interact with claw cranes and even shape the future of robotics and automation.

Mastering the claw crane control system in Stellar Blade is all about precision and timing, just like knowing the perfect destiny 2 forbearance god roll for maximum damage output. Both require a keen understanding of the mechanics and a touch of strategy to succeed, but with practice, you’ll be snagging those plush prizes and obliterating your foes in no time.